About the Customer:

World leader in production of cheese and other dairy products.

The Challenge:

Launching a new snack product containing cheese cubes packed with other snack products like nuts and other crispy snack products, the customer wanted to automate the production to keep manual handling to a minimum.

The Solution:

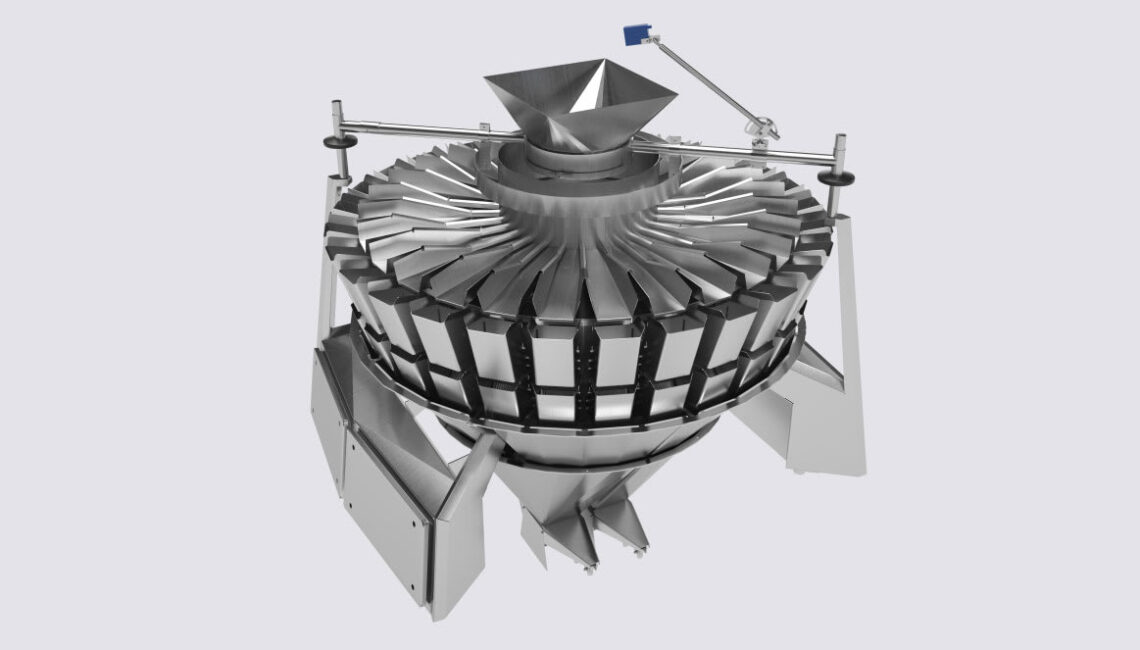

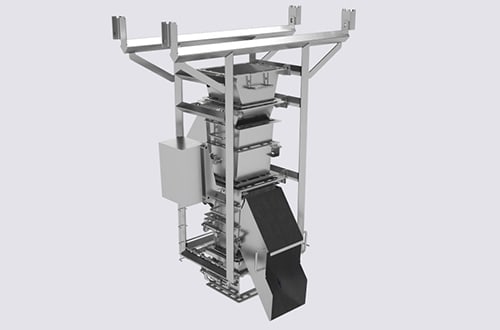

The solution included two Multihead Weighers – one for weighing cheese cubes and a divided MHW for all other snack products. The weighed-out portions are distributed into a thermoformer.

The Result:

The result is a fully automatic line with a minimum of manual handling and thus production costs are kept to a minimum.

Benefits

- All-in-one process

- Better yield

- Less labor cost

- Easy to clean

- Full tracking of raw materials and finished products

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Products in case story

Contact a specialist

We have people all around the world who can help.