About the Customer:

Frigorifer is one of the most advanced frozen vegetable processer in Eastern Europe, with a production capacity of 100 tons/day.

The Challenge:

A small and outdated vegetable processing line needed to be replaced, as Frigorifer wished to utilise an option to make contracts with local vegetable growers.

The Solution:

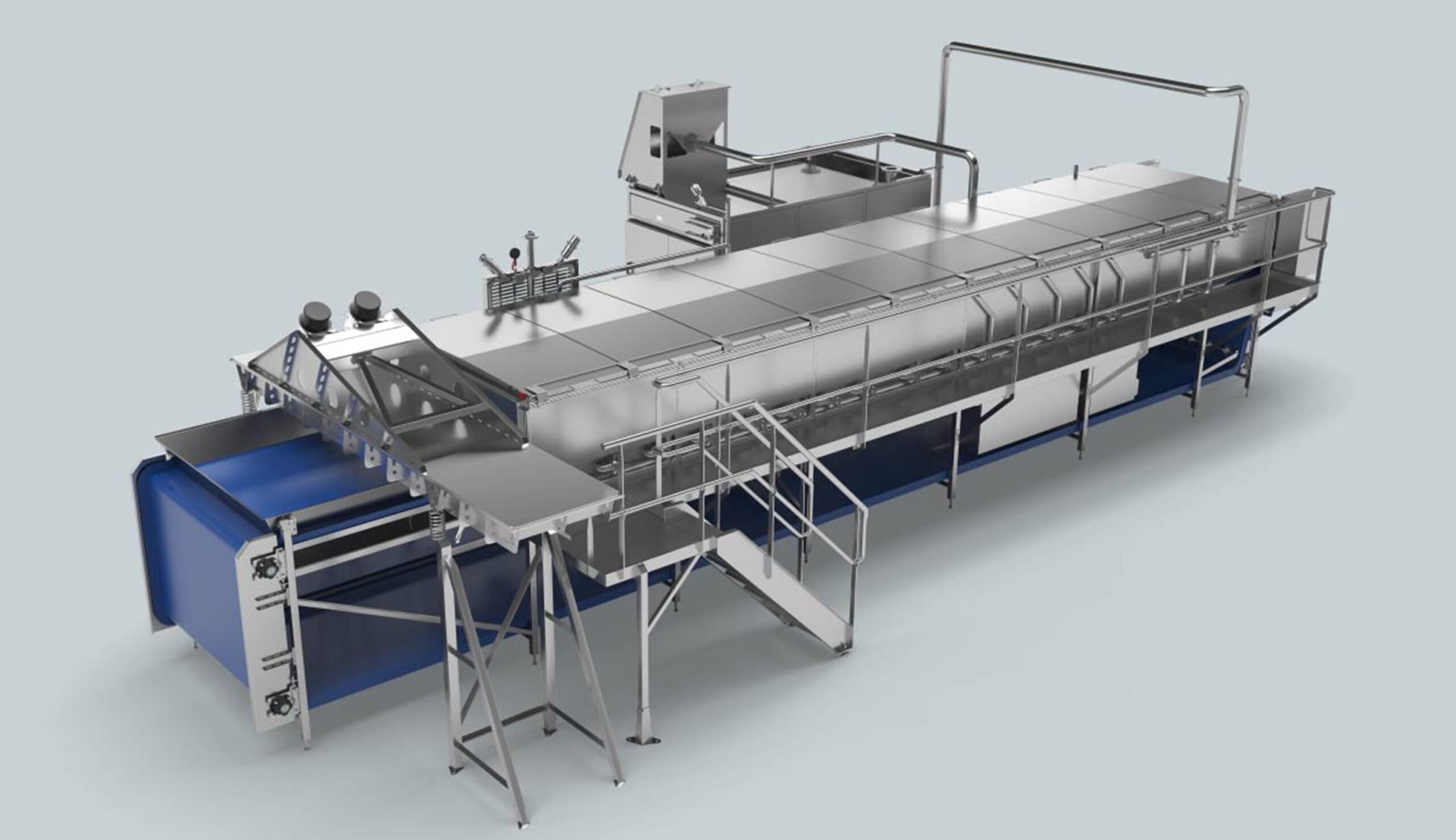

A complete Cabinplant vegetable line including steps to clean, wash, blanch, freeze, colour sort, weigh and pack peas and green beans, as well as steps to snip and cut beans. Processing of root vegetables further includes steam peeling, dicing and slicing, and the line is also prepared for future handling of spinach and corn.

The Result:

With this solution Frigorifer was able to meet all the wanted parameters. They now have complete processing solution, which has increased their yield and flexibility in regards to production capabilities. Furthermore the solution has decreased the water consumption and the lines works with recirculation of the water

“The project has been a complete turnkey project. Cabinplant has designed the layout of the process, delivered the equipment and attended to the installation and start-up of the system. We have been given some good advice on the different processes and have been very impressed by the high knowledge level of the team of people we have dealt with.”

Benefits

- All-in-one process

- Higher yield

- Continuous process

- Gentle processing

- Low water consumption

- Full tracking of raw materials and finished products

- Recirculation of water

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Products in case story

Contact a specialist

We have people all around the world who can help.

Business Segment Manager, Fruits & Vegetables

Allan Møller Hansen