About the Customer:

The customer is the largest olive processor in Turkey and employs more than 400 people.

The Challenge:

The customer has been filling trays with different size portions of olives manually, resulting in high labor cost and little automation, They therefore sought a more premise, efficient way of filling olives in thermoformed trays.

The Solution:

The customer wanted a solution capable of counting and filling olives into trays of 3 pcs., 20g, 40g, 40 x 40 mm at 160 trays per minute.

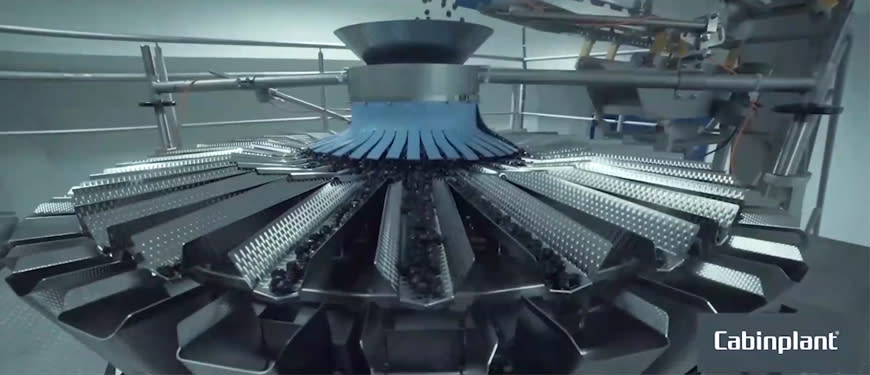

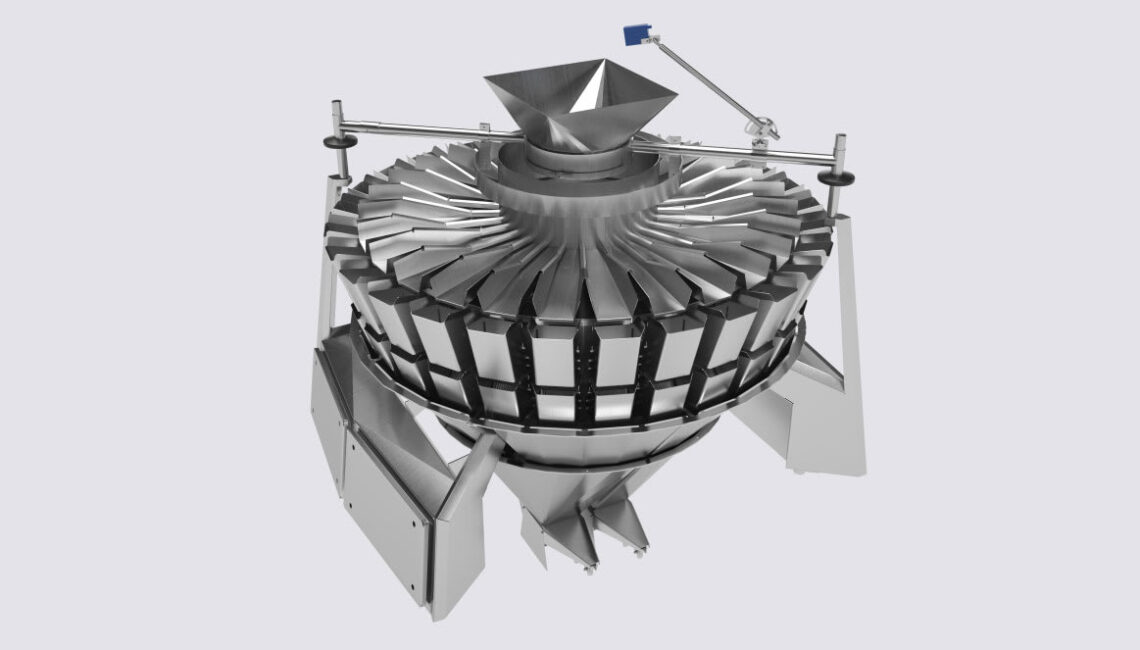

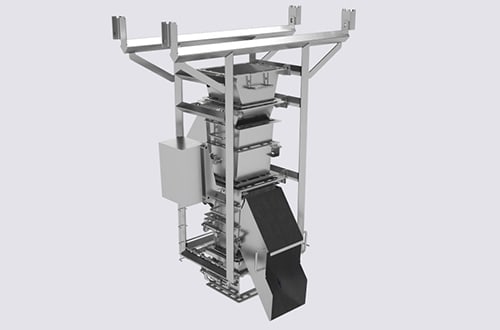

The solution to this consists of a Cabinplant Multihead Weigher 10-32 vibratory and a custom-made distribution Tool. A Liquid Filler fills oil of 3, 5 or 8 ml after the distribution tool, according to the tray size. A thermoformer is installed towards the end of the line, and the olives are packaged automatically.

The Result:

The customer is now packaging trays automatically utilizing the joint solution from Cabinplant and Mutivac, reducing cost of labor and give-away.

Benefits

- All-in-one process

- Better yield

- Less labor cost

- Easy to clean

- Full tracking of raw materials and finished products

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Products in case story

Contact a specialist

We have people all around the world who can help.

Business Segment Manager, Fruits & Vegetables

Allan Møller Hansen