About the Customer:

Our customer is a leading European meat and poultry processor. Their position as a market leader is embedded in their commitment to delivering high-quality meat and poultry products.

The Challenge:

The customer’s challenge was to efficiently deliver a diverse range of marinated products in small batches to supermarket customers. Traditionally, marinating processes are often connected with time-consuming cleaning during production changeovers, an issue with the small batches and wide variety of marinated products.

The Solution:

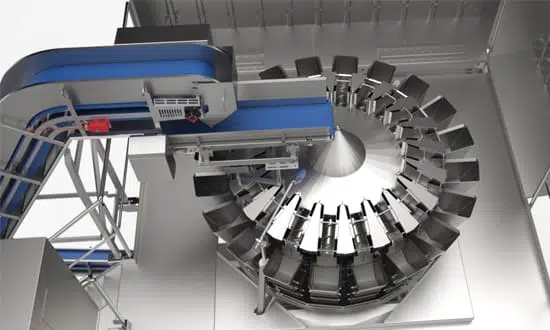

The customer’s installation of Cabinplant’s technology involved several production lines in two of the customer’s largest facilities. The key to this solution was the ability to marinate meat products efficiently and weigh them precisly. It made it possible to make accurate portions filled into trays. This shift from the conventional marinating process had several transformative effects on the client’s production process.

The Result:

This solution meant that what previously required 45 minutes for cleaning and changeover could now be accomplished in just 15 minutes, leading to increased productivity and reduced downtime.

Furthermore, the implementation of Cabinplant’s solution also impacted production speed and consistency. The automated system ensured a consistent balance of marinade volume for each meat portion, and the production line was now capable of producing 40-50 portions per minute. This remarkable improvement increased output and met the customers’ demands for effectiveness and precision.

Benefits

- All-in-one process

- Space saving

- Better yield

- Less labor cost

- Easy to clean

- Full tracking of raw materials and finished products

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Products in case story

Contact a specialist

We have people all around the world who can help.