Heat treatment

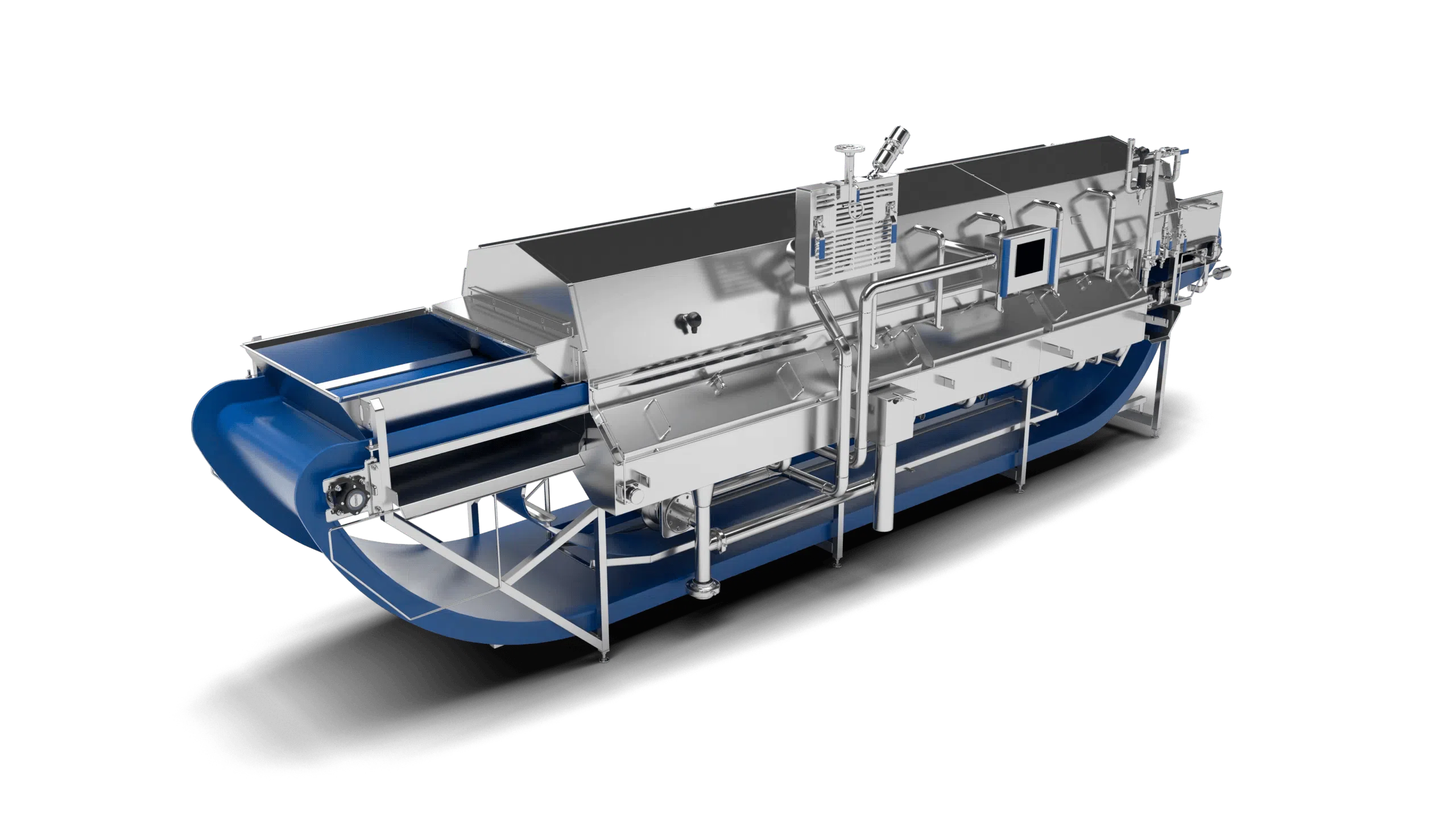

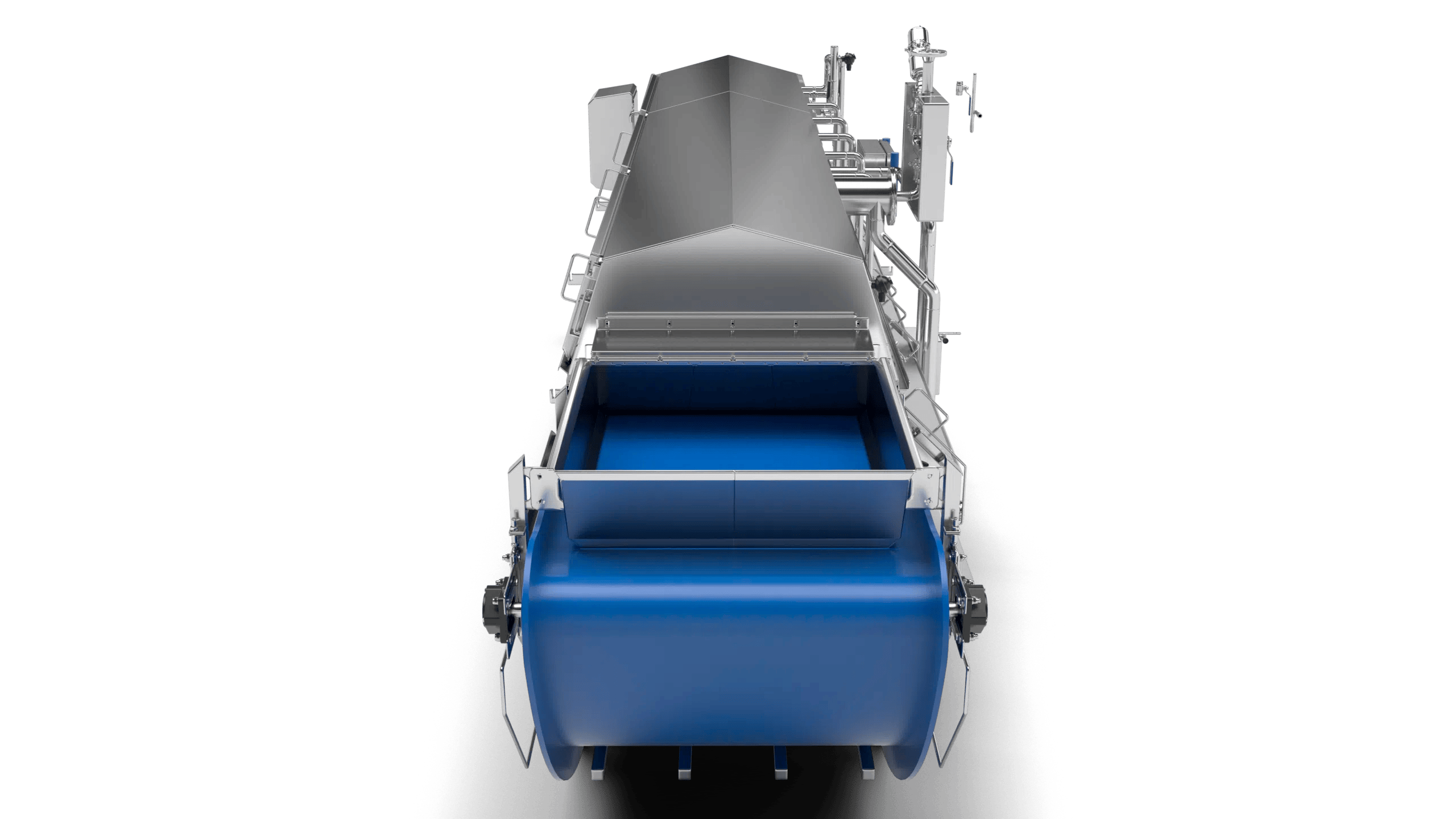

BC Blancher - Water blanching and cooling

The BC blancher/cooler is a uniquely crafted, space-efficient blancher tailored for smaller production volumes, ranging from 1 to 9 tons per hour. Additionally, the introduction of cooling water is finely tuned based on the product quantity through the utilization of a thermostatic water valve.

The BC line operates on the same basic principles as the IBC line, albeit without the pre-heating feature (available as an optional add-on). This results in increased steam consumption, but the initial purchase cost is reduced as a trade-off. Furthermore, the BC setup is less intricate but remains an attractive alternative to Cabinplant’s blanching technology.

Download our brochure below and learn more about our BC blancher

Download"*" indicates required fields

Integrated blancher and cooler

Low risk of product contamination

Customer-adapted design

The basic version consist of:

- An infeed section where the product is introduced and uniformly distributed onto the blanching belt.

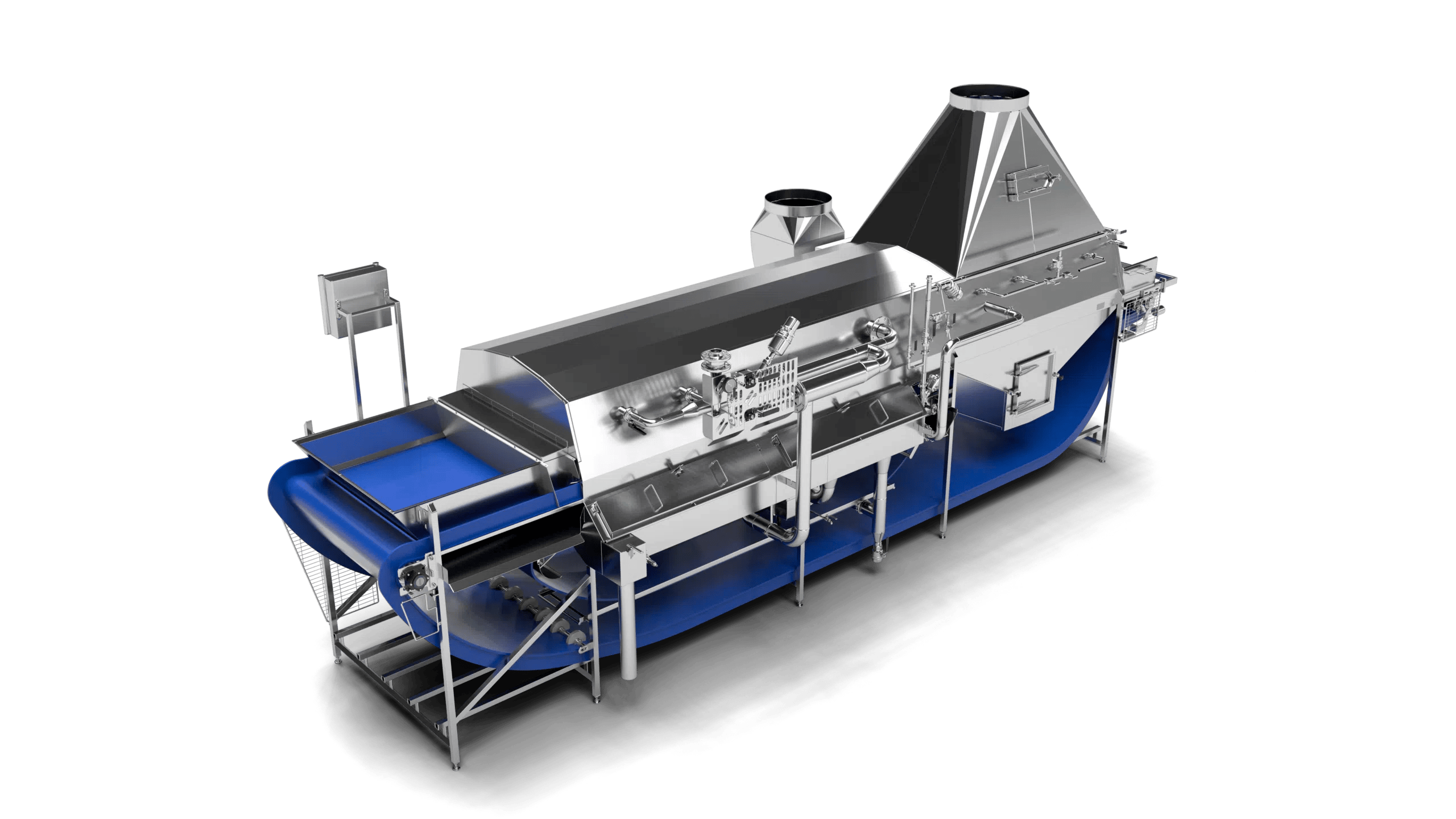

- A dedicated blanching section responsible for heating the product. This is accomplished by gently spraying it with recirculated water, which is heated using precisely controlled injected live steam regulated by a modulating steam control valve.

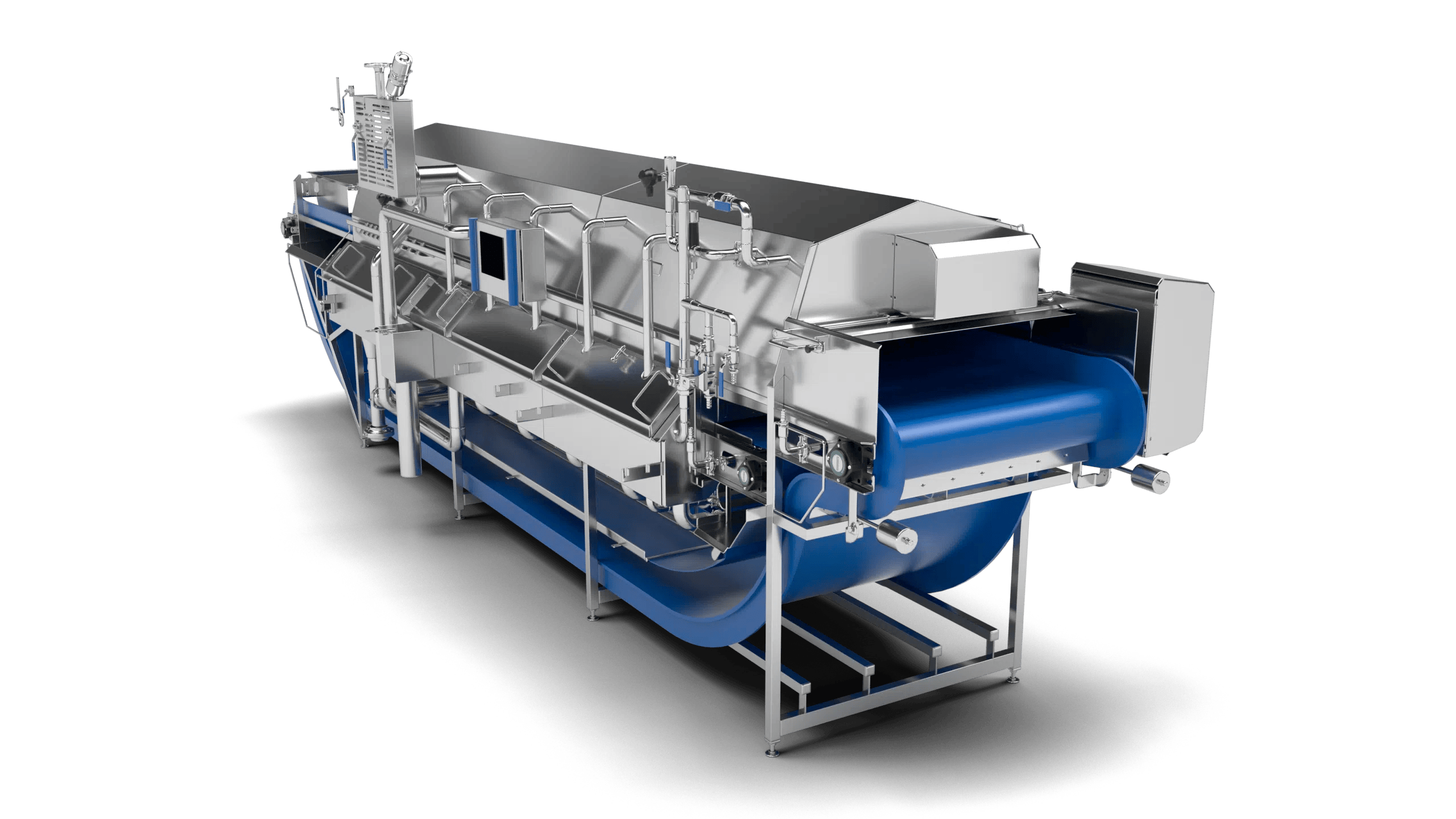

- A dedicated cooling section where cooling water is actively pumped to efficiently cool the product. This process is executed in a counterflow manner relative to the product’s path, ensuring optimal temperature reduction.

Optional

The thermal energy derived from the heated cooling water can be effectively utilized to benefit the infeed section by facilitating the rinsing and, to a certain extent, preheating of the incoming product. This ensures a more efficient and sustainable use of resources in the process

Features and advantages

- Low risk of product contamination even

after long operating hours - Integrated blancher and cooler

- No product damage

- High yield

- Uniform blanching

- Multistage counterflow water circulation

ensures extremely low water consumption

and waste water discharge - Additional lowering of product temperature

by means of recirculated chilled water, option - Customer-adapted design

Technical data

| BC Basic Version | BC 2 | BC 3 | BC 4 | BC 6 | BC 9 |

| Nominal Capacity for Green Pears Kg/h | 2,000 | 3,000 | 4,000 | 6,000 | 9,000 |

| Overall Length m | 4,3 | 5,8 | 7,3 | 7,3 | 10,3 |

| Steam Consumption max. Kg/h | 450 | 625 | 800 | 1,100 | 1,600 |

| Water Consumption kW | 6 | 7,5 | 9 | 13 | 20 |

| Nominal Power Consumption kW | 4 | 5 | 7 | 9 | 12 |

Product gallery

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Related products

Contact a specialist

We have people all around the world who can help.

Business Segment Manager, Fruits & Vegetables

Allan Møller Hansen