Heat treatment

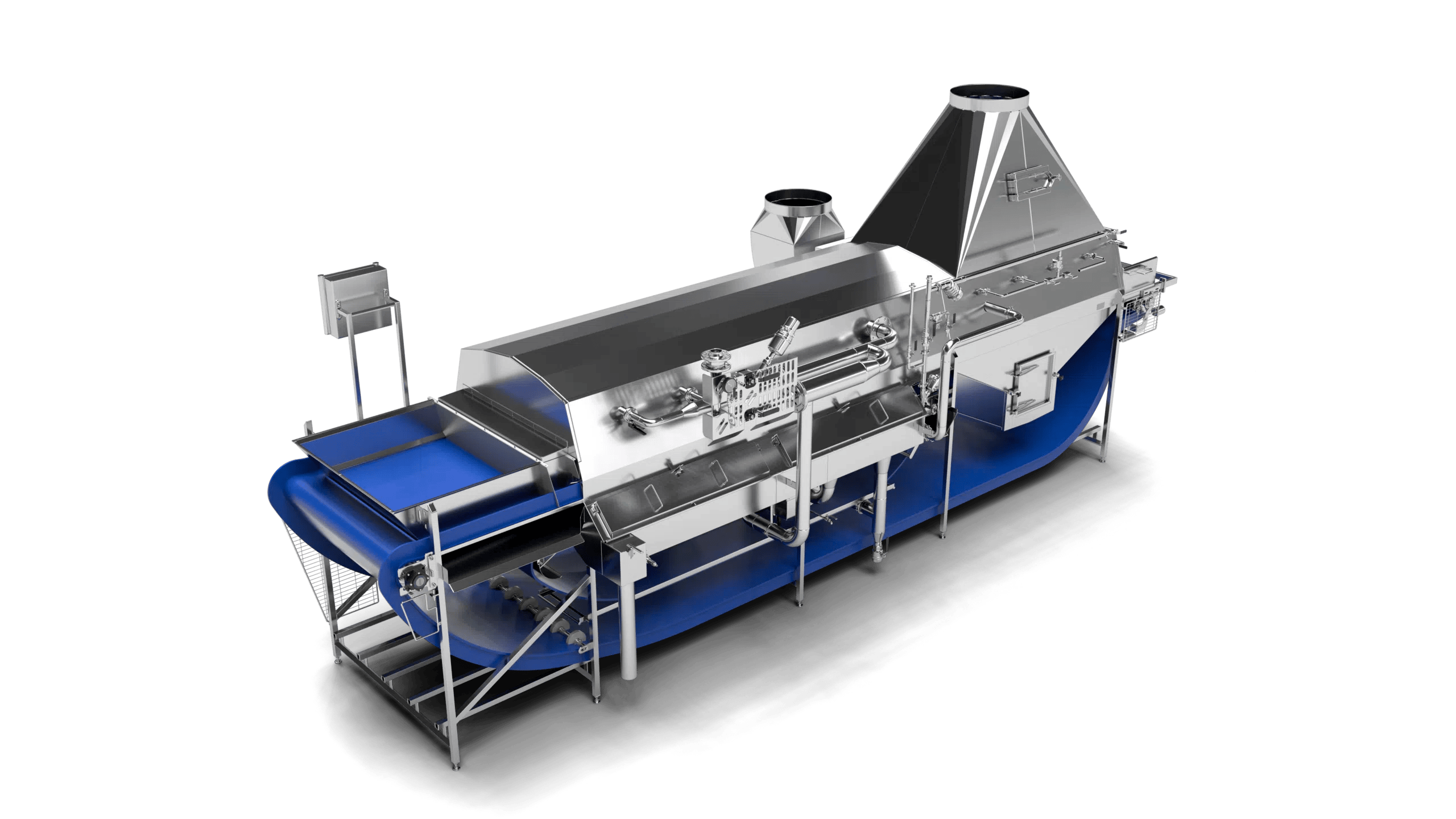

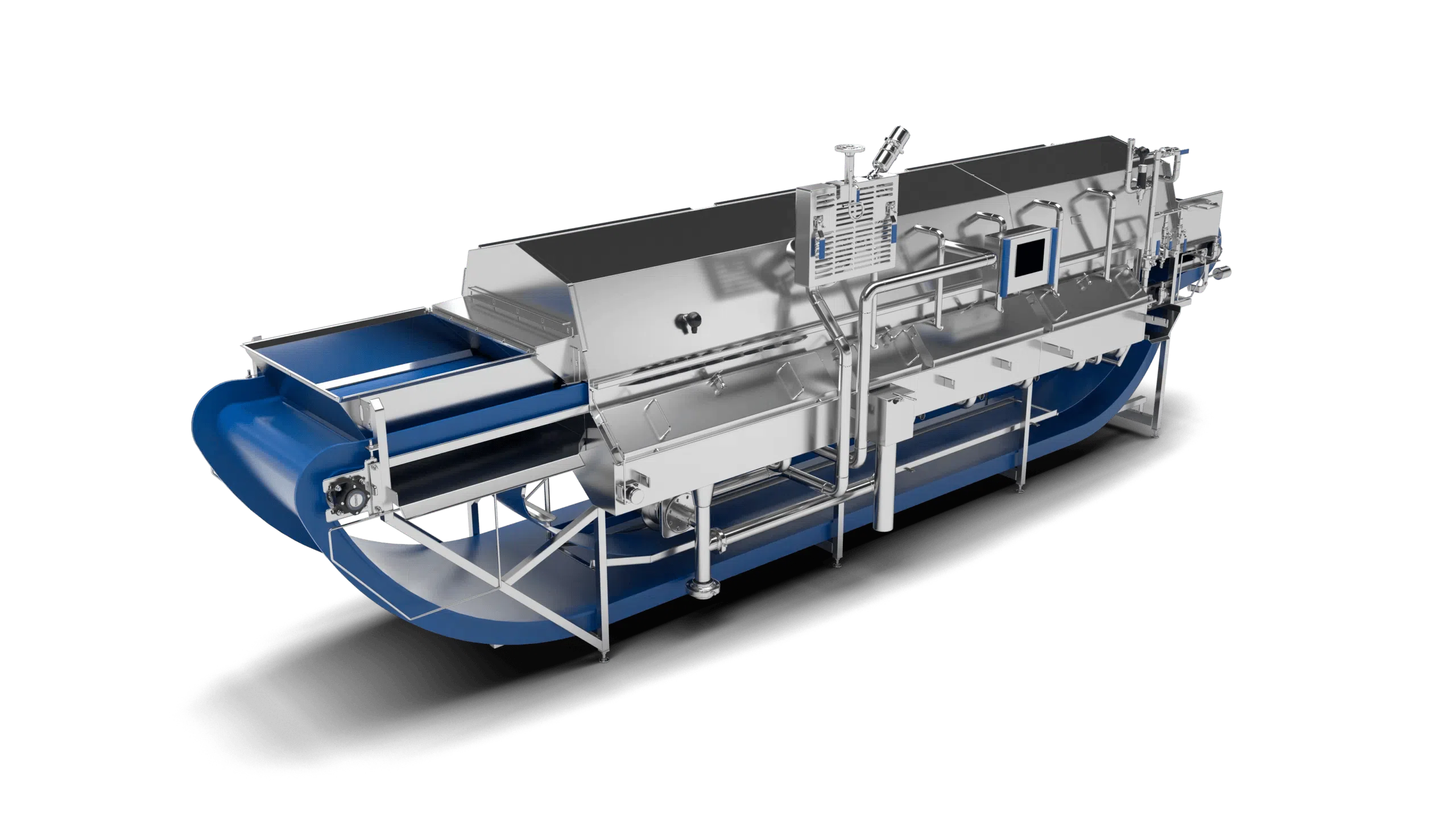

IBC Blancher w. Forced steam

Cabinplant’s IBC blancher with forced stream has a cutting-edge integrated cooling section featuring a state-of-the-art counterflow cooling system. This innovation conserves water during the cooling process. The Blancher allows for efficient pre-heating, leading to remarkable reductions in steam consumption—up to 50-60% less than conventional blanchers without pre-heating capabilities. With the flexibility to tailor product discharge temperatures to your needs, you can maintain an optimal temperature of around 12°C when using 1°C cooling water.

Download our brochure below and learn more about our IBC blancher with forced steam

Download"*" indicates required fields

Reduce water / steam consumtion by up to 60%

Highly uniform blanching of fruit and vegetables

Increased food safety

Choose the best way of heating your product.

Opt for the optimal heating approach for your product. Our blancher offers 100% flexibility, allowing you to heat using either hot water or steam distributed by fans within the blanching section, resulting in uniform heat distribution akin to water blanching. Customize your process by employing forced steam for items like broccoli and water blanching for peas, offering complete control over your heating method.

Reduce steam consumption significantly.

Our integrated cooling section, equipped with a counterflow cooling system, minimizes water usage during cooling and enables efficient pre-heating, leading to 50-60% steam consumption reductions compared to non-preheating blanchers. Product discharge temperature is typically around 12°C with approximately 1°C cooling water, but lower temperatures can be achieved upon request.

Additional options

The Forced steam blancher coupled with ambient air cooling or chilled air cooling is another combination beneficial for more water-sensitive products. This is ideal for products where avoiding water treatment is essential to prevent starch and sugar loss, such as potato dice, slices, whole potatoes, and even cut corn. The blancher includes the following features:

- Top-lift for easy access to the inside of the machine

- CIP system

- Stainless steel motors/pumps

The forced steam and water and water blancher with water cooling is suitable for blanching peas, rice, cut corn, broccoli, and more, optimized for log 5 blanching. It offers complete flexibility in customizing your product to meet customer preferences for color, taste, and starch levels. Hygiene is a top priority because this machine is used for ready-to-eat products. It combines forced steam and water blanching with water cooling and includes the following features:

- Convenient top-lift design for easy access to the machine’s interior.

- Special hygienic water distribution system.

- Sturdy drive shafts

- Sanitary dairy valves.

Features & benefits

- Low risk of product contamination even after long operating hours

- Integrated blancher and cooler

- No product damage

- High yield

- Uniform blanching

- High degree of flexibility with regard to blanching time and temperature

- Multistage counterflow water circulation ensures extremely low water consumption and waste water discharge

- Additional lowering of product temperature by means of recirculated chilled water.

- Customer-adapted design

- Line solution flexibility – ability to run different products

Product gallery

Contact us today to learn more about our IBC blanching solutions

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Related products

Contact a specialist

We have people all around the world who can help.

Business Segment Manager, Fruits & Vegetables

Allan Møller Hansen