Preperation Automation

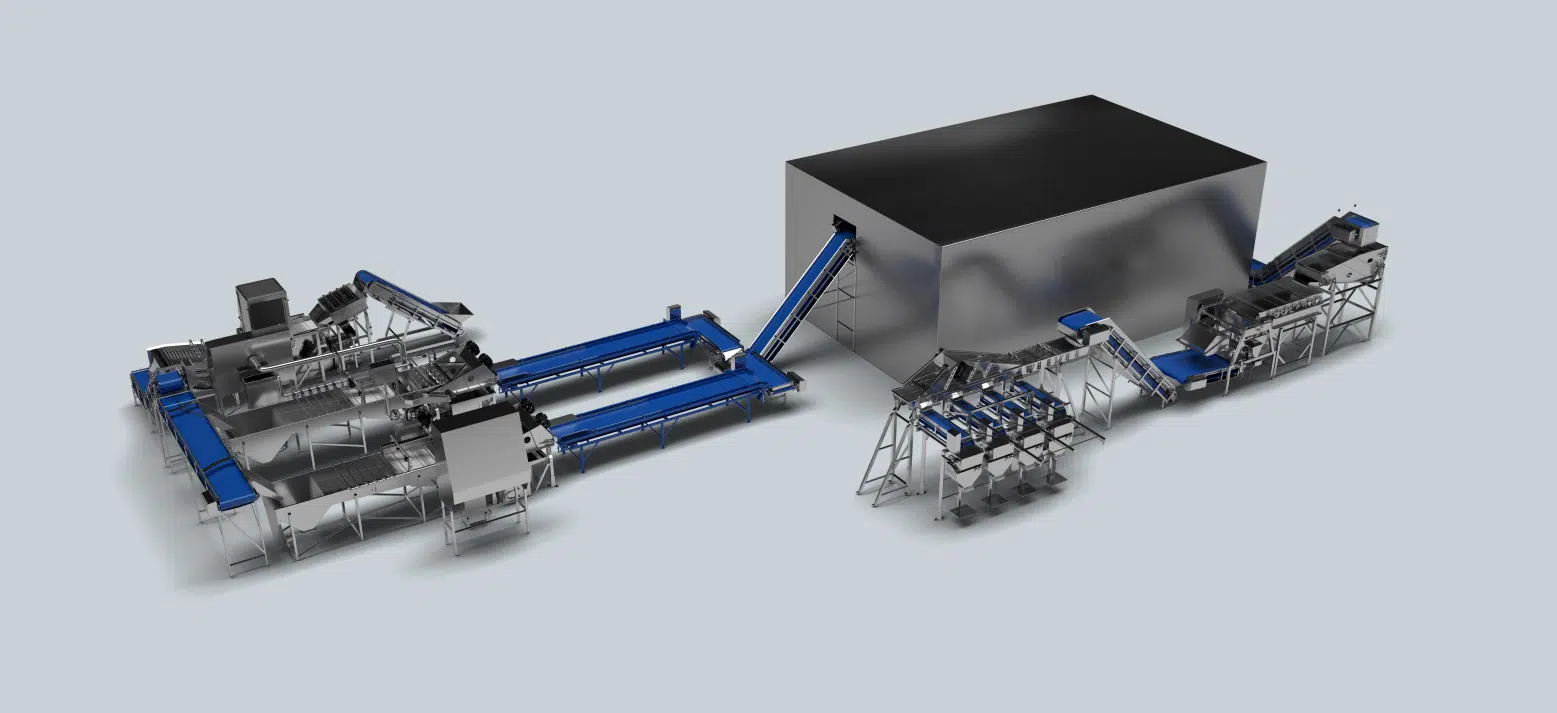

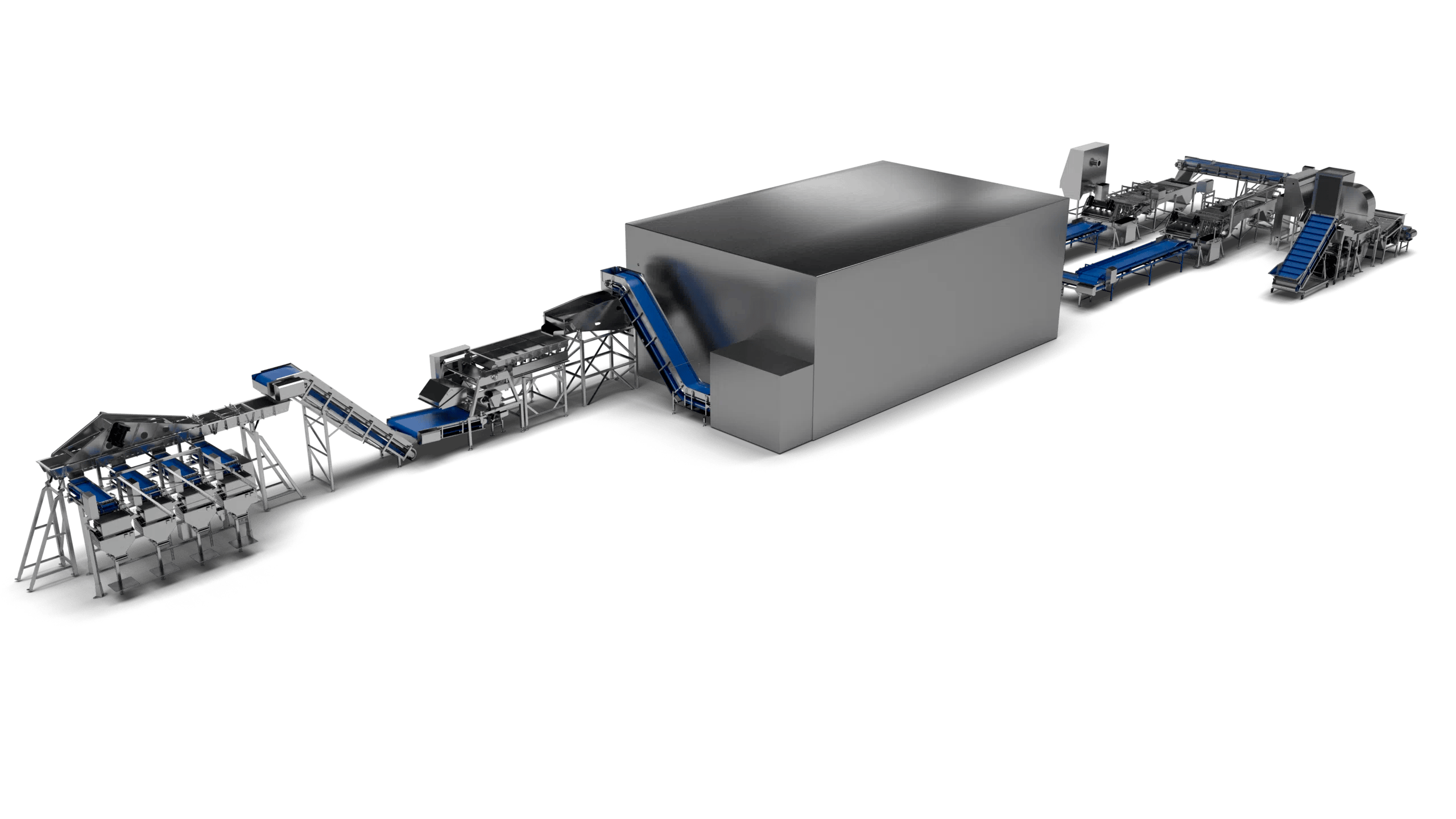

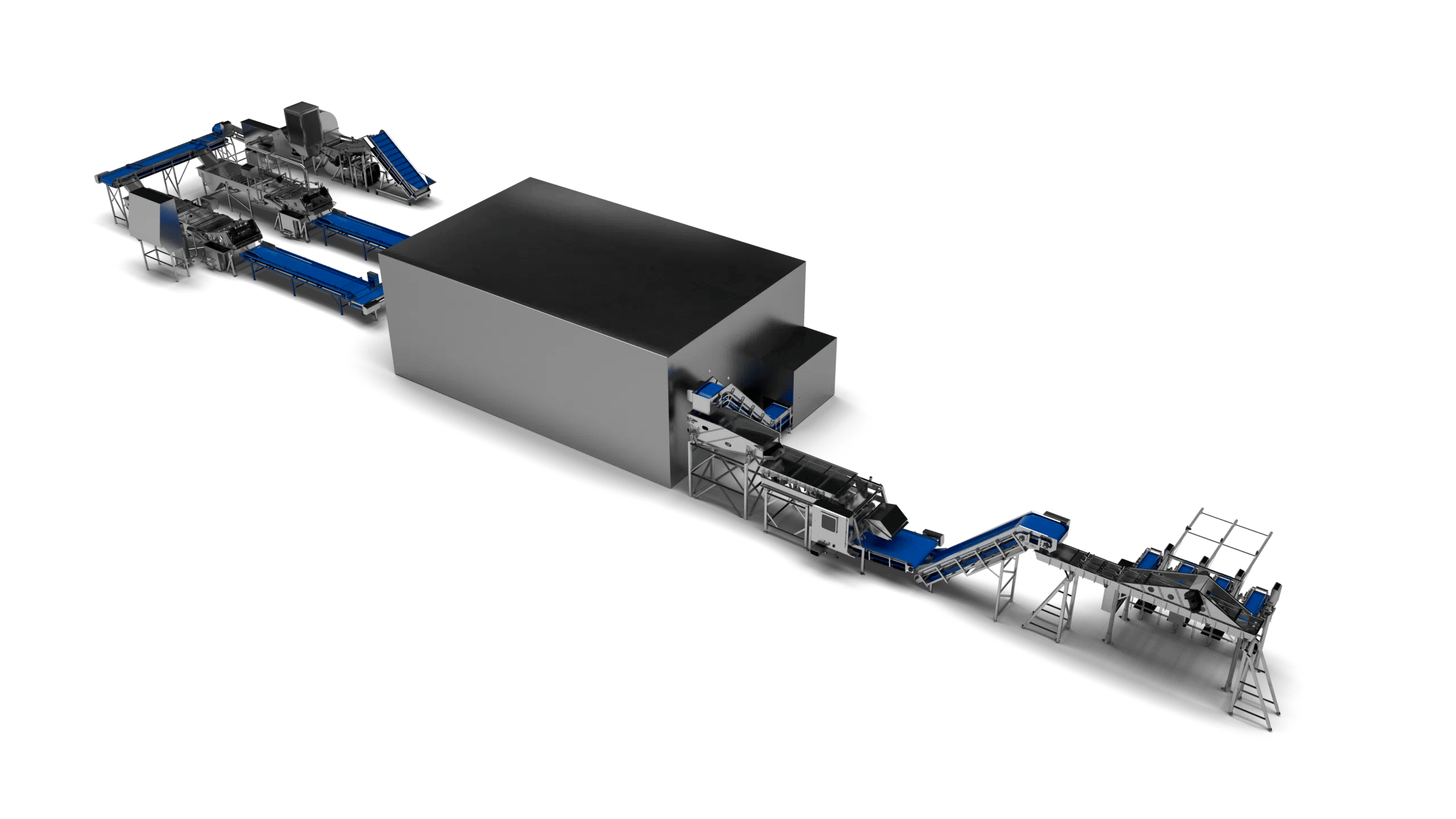

IQF Strawberry Line

The Cabinplant IQF Strawberry line, with gentle treatment and a thorough cleaning process, is perfect to optimize your pre-freezing and packaging process for your Strawberry production.

Our comprehensive equipment line-up ensures that your strawberries undergo gentle treatment throughout the process, resulting in a premium end product.

Delicate treatment, comprehensive cleaning, and optimal sorting are vital parameters to ensure premium quality preservation and packing of your strawberries.

Therefore, our IQF Strawberry line has the ability to do everything from sorting and grading to washing, weighing, and packing. We’ve got you covered. If pre-freeze cutting is part of your process, we’re here to handle that seamlessly.

Download"*" indicates required fields

Gentle handling

Optimal Sorting

Efficient cleaning

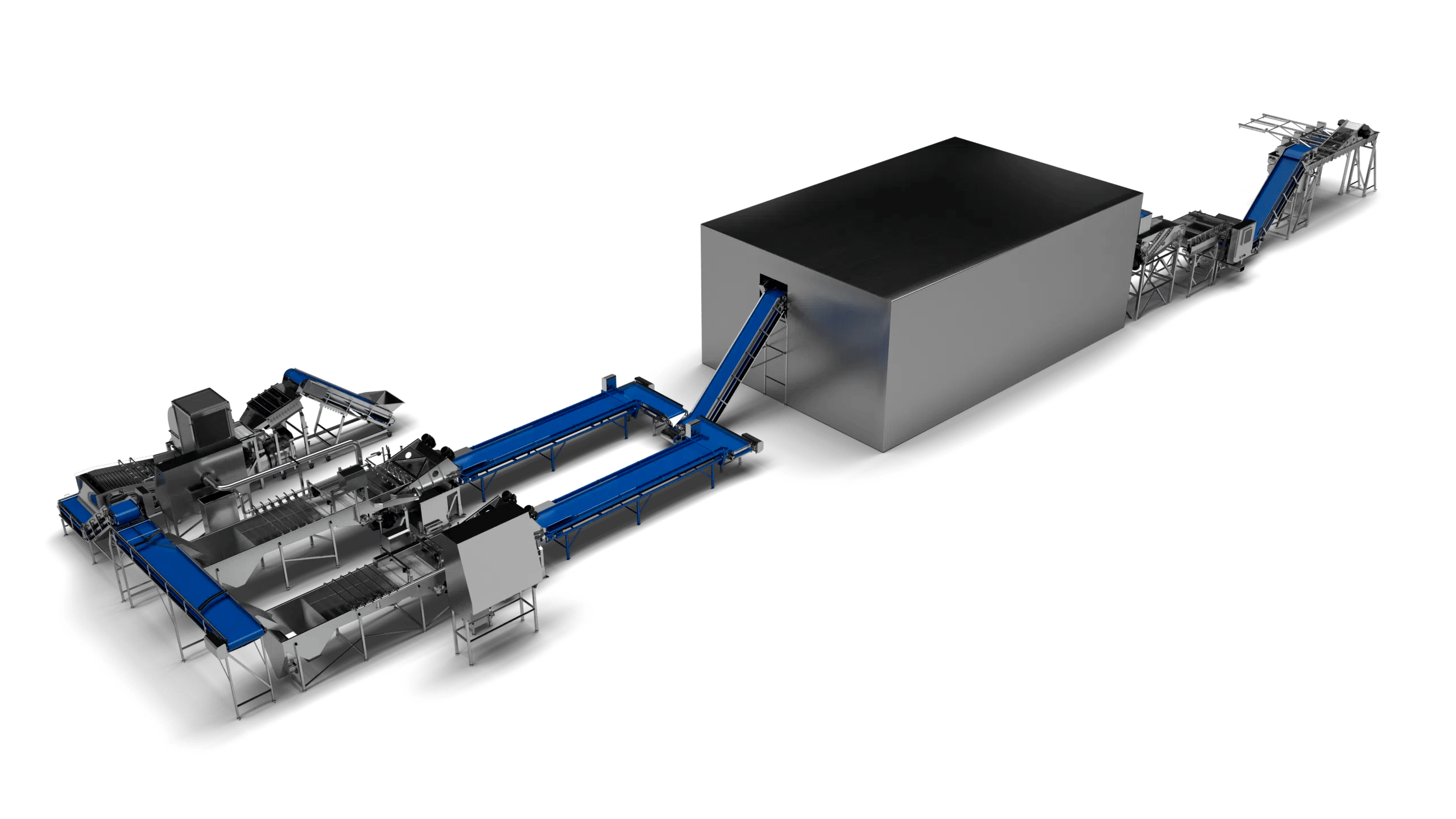

Optimal Sorting

Optical sorting plays a crucial role in your processing procedures. Complying with food safety standards and attaining higher product purity is vital. Our capability involves the implementation of various sorting machinery, employing a spectrum of technologies such as cameras, lighting, and machine learning software. This technology effectively eliminates imperfections and extraneous substances based on factors like color, shape, and texture.

Type of cleaning:

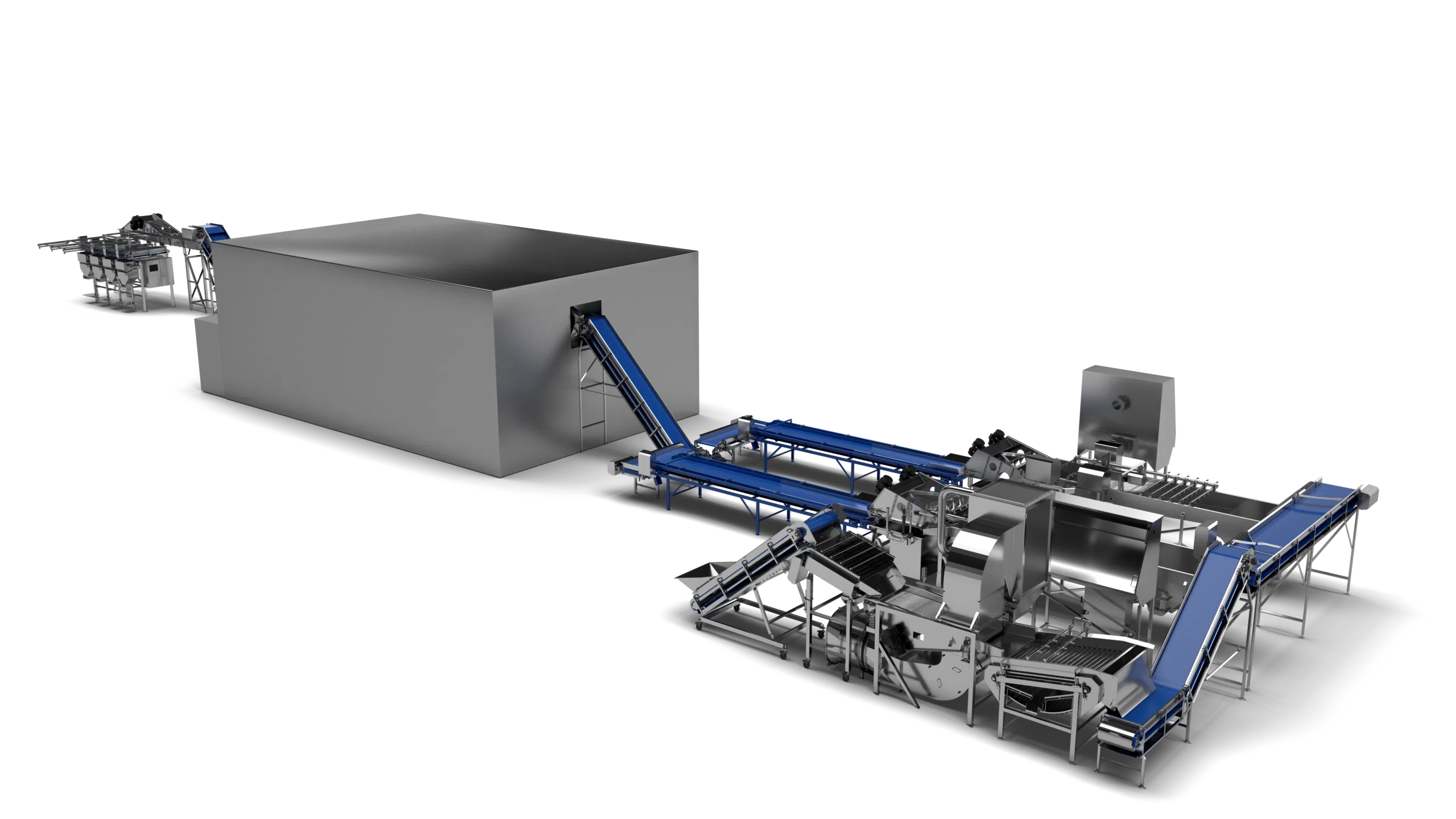

Cleaning/ washing the strawberries is crucial in ensuring a premium product. The different growing environments affect how much cleaning is needed. A Strawberry cleaning system can include, but is not limited to:

- Air cleaning for removal of leaves and light debris

- Separation on vibrating screens of non-threshed pods in harvesting machines

- Flotation wash for removal of floating foreign matter as well as dirt and small stones from the product

- Mechanical cleaning of recirculated water to reduce water consumption

- Mechanical collection, conveyance, and central discharge of all waste from the described process

- Manual inspection and trimming of berries

- Baudelot water chiller to keep the washing water cold, thereby protecting the berry quality

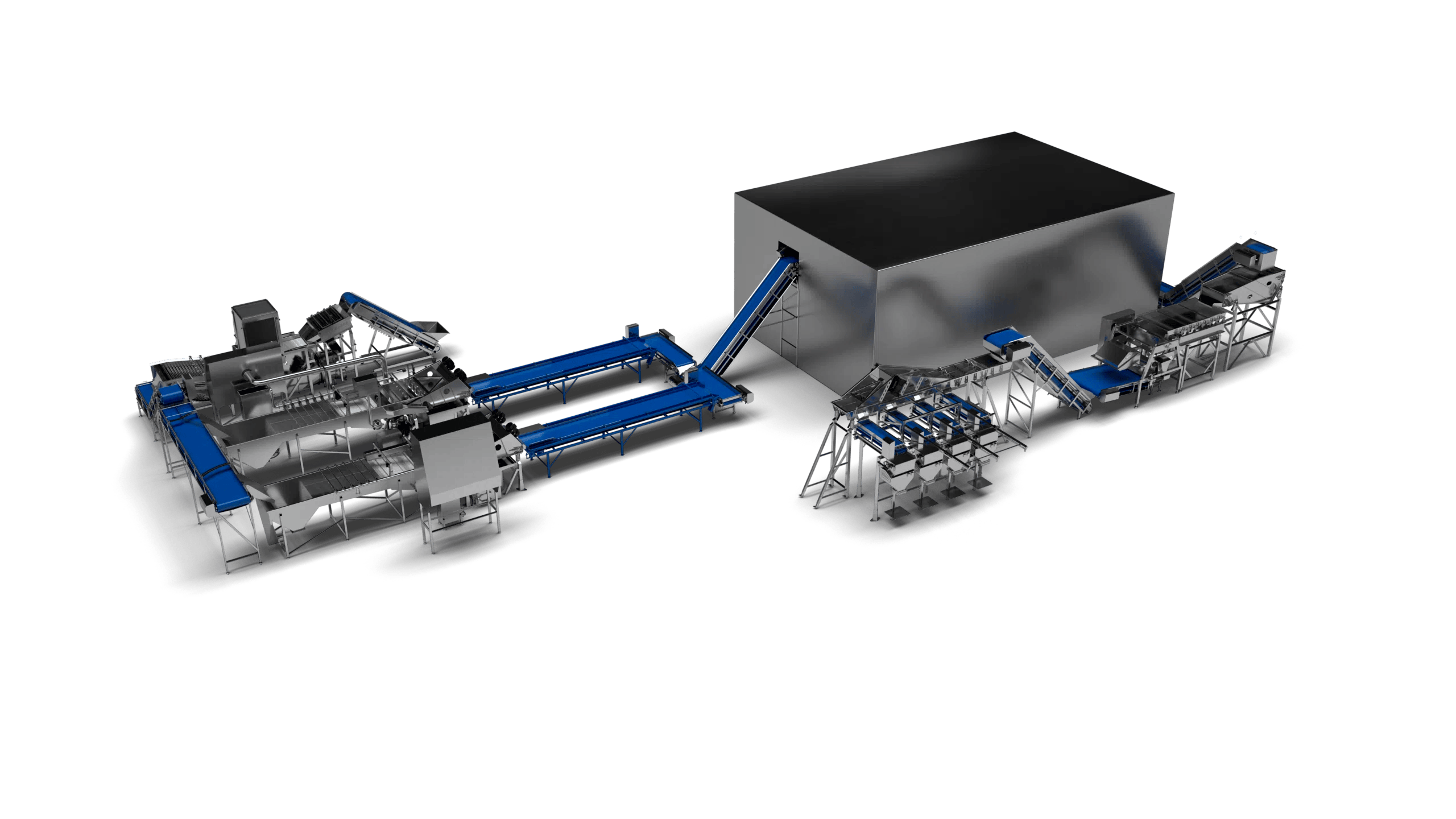

Size grading and glazing

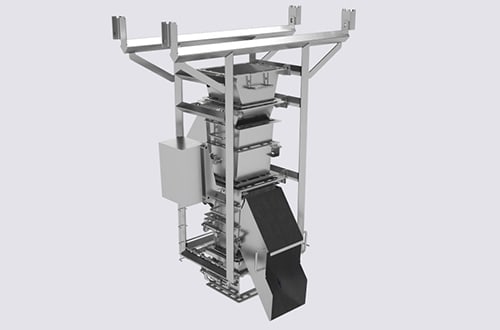

When temperatures drop below freezing, the product is raised to a vibrating sizing grader, where it is sorted into four distinct grades. Each of these grades is then directed to separate packing stations. If desired, an additional glazing step can be incorporated before packing. During the glazing process, the water volume can be adjusted according to the various sizes of the product. This optimization ensures optimal weight gain without requiring the berries to undergo defrosting.

Packing

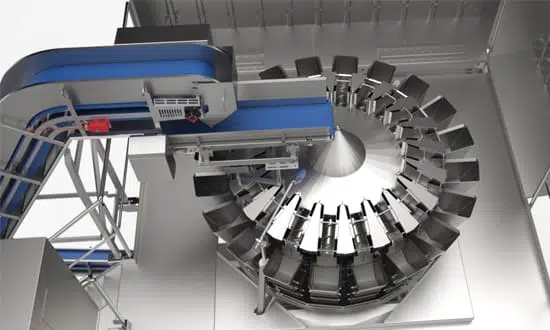

In our capabilities, every grade undergoes packing prior to entry into the cold storage. The packing process usually involves placing the product into cardboard boxes weighing between 5 to 10 kg. This can be accomplished through batch or multihead weighers based on the required capacities. Furthermore, the option of packing into retail bags, such as 500g bags, is also within our purview at Cabinplant.

Allow us to assist you in designing your cutting-edge strawberry processing line. Over the years, Cabinplant has designed, constructed, and implemented numerous strawberry lines for clients exporting strawberries to Japan. In this market, where product quality tolerates no errors, our experience speaks volumes.

Features & benefits

- Gentle Treatment

- Comprehensive cleaning

- Efficient workflow

- Minimum noise level

- Minimum maintenance

- Easy cleaning

- Customizable Solutions

- Optimal Glazing

- Seamless integration

- Hygienic design

- Cutting-Edge Technology

Product gallery

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Related products

Contact a specialist

We have people all around the world who can help.

Business Segment Manager, Fruits & Vegetables

Allan Møller Hansen