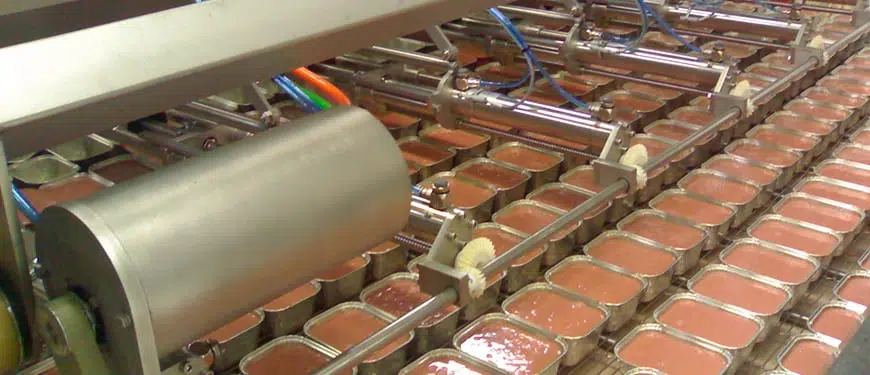

Dosing/Filling

Piston filler - Automatic accurate filling of liquids

Cabinplant automatic piston fillers are designed for fast and accurate filling of liquids, matching required capacity, viscosity and filling volume. The filling valves can be fixed or mounted to follow the packing material for a higher capacity.

The fillers are designed to match required capacity, viscosity and filling volume.

The piston fillers can handle products such as sauce, oil,

marinade and mayonnaise.

Download our brochure below and learn more about our Piston fillers

Download"*" indicates required fields

Accurate filling

Easy to clean

Reduced give-way

The piston filler is custom-made to meet individual needs

The piston filler consists of stainless steel hopper with removable cover and sensor for detection of product level in tank. The hopper can be equipped with one rotary agitator for product mixing at your option.

The piston filler is fitted either with a pneumatic cylinder (fully automatic piston filler) or a servo-operated spindle motor (fully electronic double piston filler). A servo-operated spindle motor ensures optimum liquid handling.

Functionality of the pistonfiller

The piston filler can be provided either as an individual machine or as part of a complete processing line, e.g. a ready-meal line.

The special design of Cabinplant piston fillers ensures easy and safe cleaning and meets the high cleaning demands of the food industry. Product wetted parts can be dismantled without the use of tools for thorough cleaning and sterilization.

The fillers are designed to match required capacity, viscosity and filling volume. Advantages include:

- Recipe control to ensure swift production change-over

- Specially designed filling heads with cut-off system to prevent drip and spillage

- Even distribution of liquid across the product in e.g trays

Features & benefits

- Accurate filling

- “No can – No fill” system

- Reduced give-way

- Easy cleaning

- Low maintenance

- Sauce

- Oil and brine

- Marinade

- Soup

- Mayonnaise

- Remoulade (tartare sauce)

- Liver pâté

- The filling volume is up to 2 litres each filling. Capacity depends on product viscosity and quantity.

Product gallery

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Related products

Contact a specialist

We have people all around the world who can help.