Thawing

Thawing Tunnel

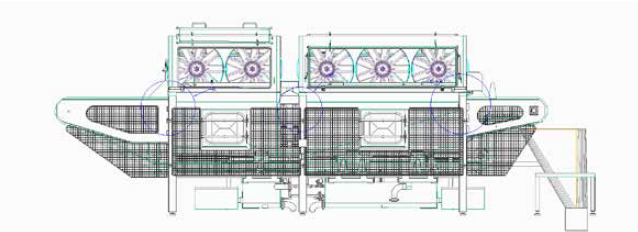

The Cabinplant Thawing Tunnel is engineered to handle the efficient thawing of Individually Quick Frozen (IQF) products, ensuring optimal product quality and throughput. Upon loading at the infeed end, the frozen product is gradually conveyed through a series of precisely controlled thawing zones within the tunnel.

A capacity of 4-5 tons product per hour

A thawing time in between 2-20 min - depending on the product and machine size

A product infeed temperature of -25 Celsius

Technical Data

- Infeed Temperature: -25°C

- Thawing Time: 2-20 minutes (varies depending on product type, size, and machine configuration)

- Capacity: 4-5 tons of product per hour

- Use: Fish, meat, and other products

This highly adaptable thawing tunnel machine ensures efficient and uniform thawing, with features designed to maintain product quality, hygiene, and throughput. Its robust construction and advanced control systems make it an ideal choice for any industrial food processing operation requiring reliable and consistent thawing of frozen products.

The tunnel utilizes by preference direct steam heating or heating pipes combined with heated air circulation to evenly and consistently raise the temperature of the product.

Features & benefits

- Electronically Controlled Chamber

- Direct Steam Heating

- Heated Air Circulation

- Conveyor Belt Disinfection System

- Modular Thawing Zones

Technical Dimensions

| Model/Size/Fans | No. of fan sections | Length | Width | Height |

| TT 2/1 | 3 | 3700 | 2400 | 2360 |

| TT 2/2 | 4 | 4450 | 2400 | 2360 |

| TT 3/2 | 5 | 5200 | 2400 | 2360 |

| TT 3/3 | 6 | 5950 | 2400 | 2360 |

| TT 3/3/2 | 8 | 6700 | 2400 | 2360 |

| TT 3/3/3 | 9 | 8400 | 2400 | 2360 |

Product gallery

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Related products

Contact a specialist

We have people all around the world who can help.

Have a question?

We’re here to help

Looking for the right solution for your food processing needs? Our team of specialists is ready to help you optimize your production, reduce waste, and boost efficiency. Reach out to us today — let’s explore how we can support your business.

Phone: +45 6373 2020

Email: cpi@cabinplant.com