Tasty convenience food made easy with flexible convenience food processing equipment

Ready, set, serve. Ready-to-Eat food

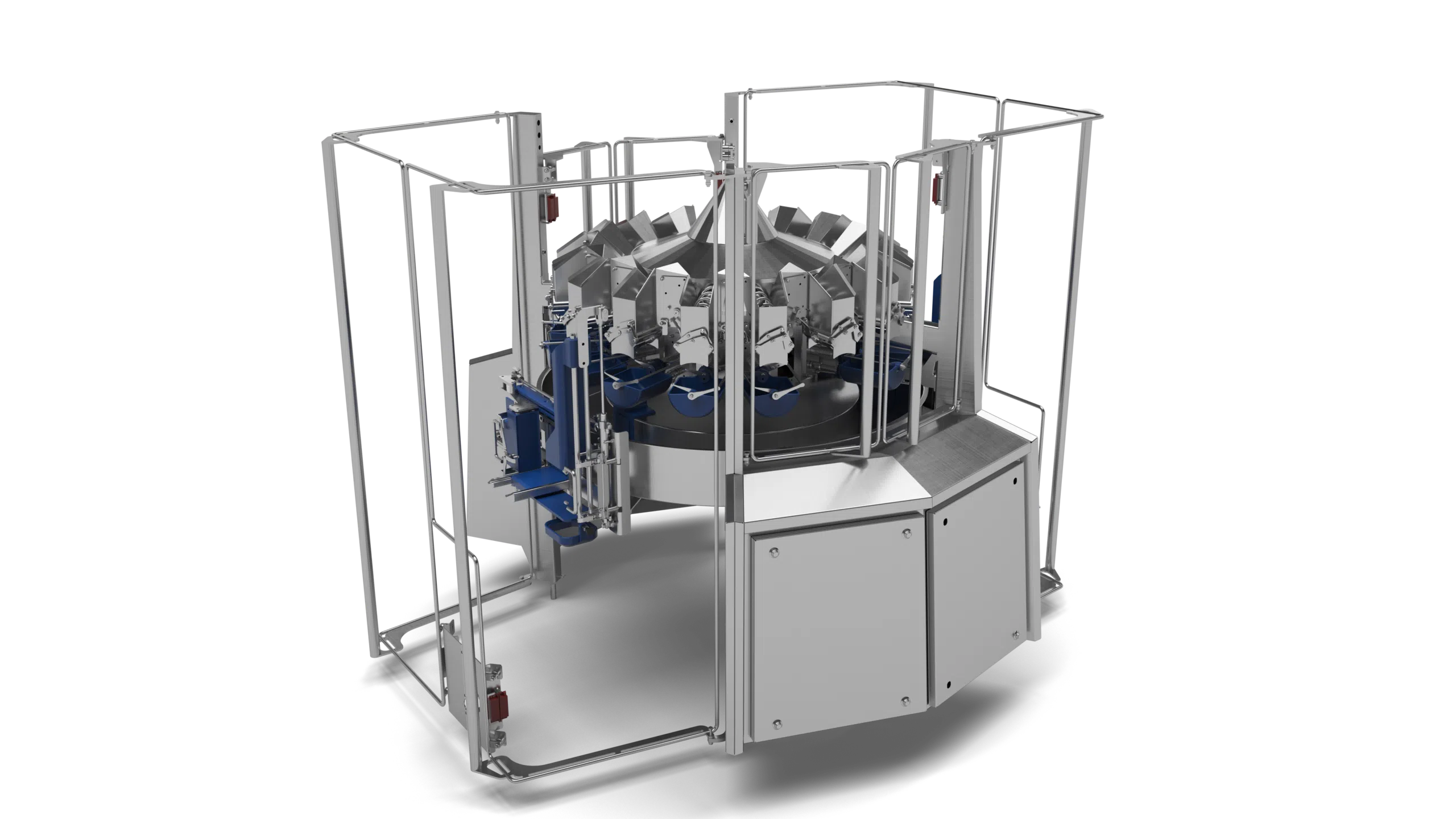

Convenience food processing equipment from Cabinplant is designed to make ready meals and ready-to-eat food production simple, flexible and efficient. Our systems help you produce high quality convenience food that looks great, tastes delicious and meets the highest safety standards.

Working with convenience food often involves complex processes and multiple ingredients that must come together perfectly. As an experienced convenience food equipment manufacturer, we understand these challenges and develop technology that simplifies them. Our automated systems streamline your workflow, reduce labor needs and secure stable, efficient production from start to finish.

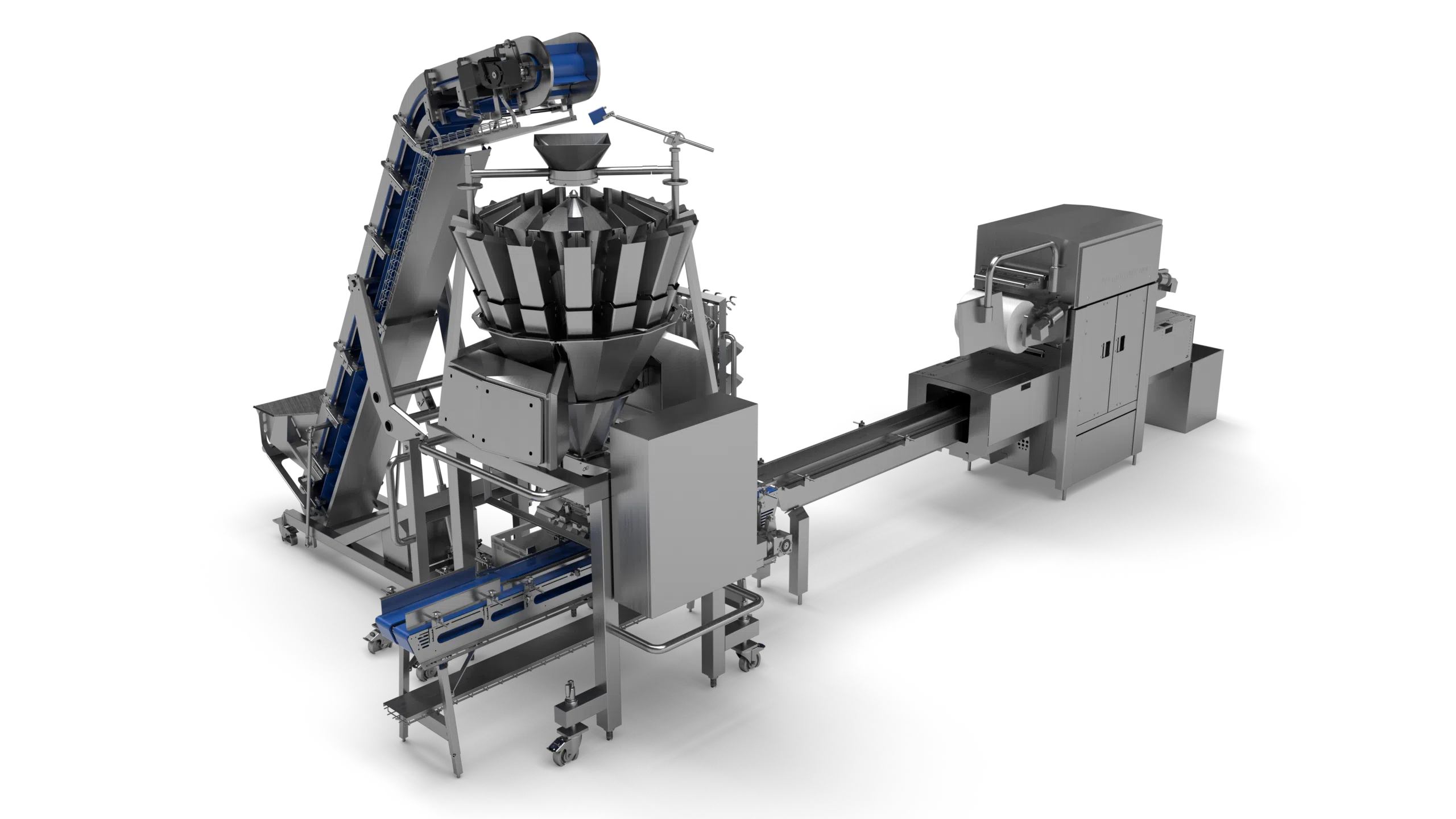

The demand for ready meals and fresh prepared food continues to grow, and producers need reliable solutions to stay competitive. Our convenience food processing solutions give you precise control over weighing, mixing and portioning. The systems can handle up to ten ingredients at once, allowing you to create different recipes quickly and consistently while reducing waste and giveaway.

Cabinplant equipment provides the flexibility and reliability you need to deliver quality and efficiency in every batch. Faster changeovers, improved productivity and consistent results make it easier to meet market demands and increase profitability. With Cabinplant as your partner, you are ready for the future of convenience food production.

Automated solutions to reduce labor requirements

Boost productivity, enhance product quality, improve traceability, and gain control over your giveaways.

Adaptable solutions designed to accommodate all your product recipes.

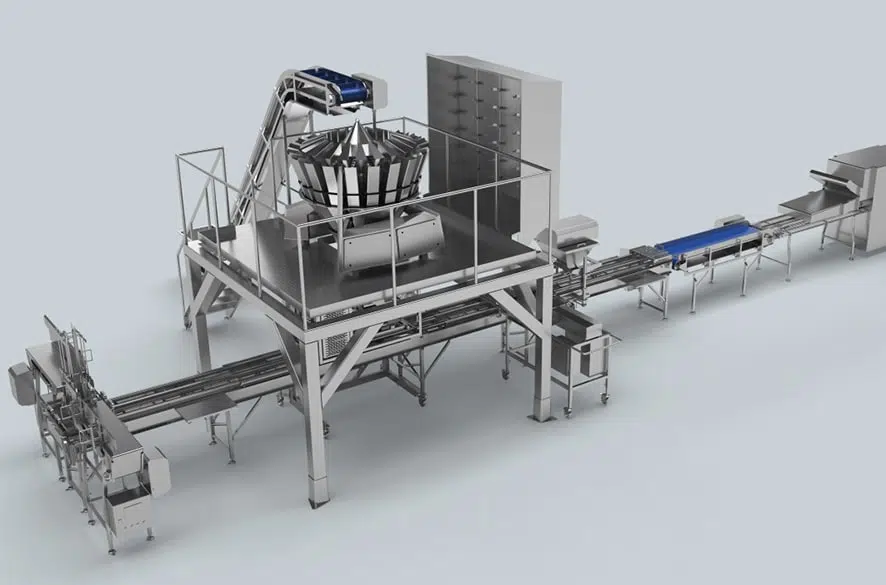

Selected complete processing solutions to improve your production

Increased demands and changing markets

Convenience food processing equipment plays a key role in meeting the expectations of today’s fast-moving food industry. With more disposable income and less time for cooking, consumers increasingly rely on ready-made meals and pre-cooked food to simplify their everyday lives.

At the same time, they expect premium quality, authentic taste and natural ingredients. This creates new challenges and opportunities for producers, as convenience food must now deliver both speed and excellence. As a trusted convenience food equipment manufacturer, we help you meet these demands through innovative technology and smart design.

Our tailored convenience food processing solutions are created to support producers who want to enhance efficiency, increase yield and maintain high product quality. Whether you produce pasta dishes, soups, rice meals or mixed salads, our systems are built to handle complex recipes with accuracy and care.

If you are working within the convenience food industry and want to learn more about how we can help improve your process, contact your local Cabinplant representative. Together we can develop a customized solution that fits your production and supports your goals for growth and quality.

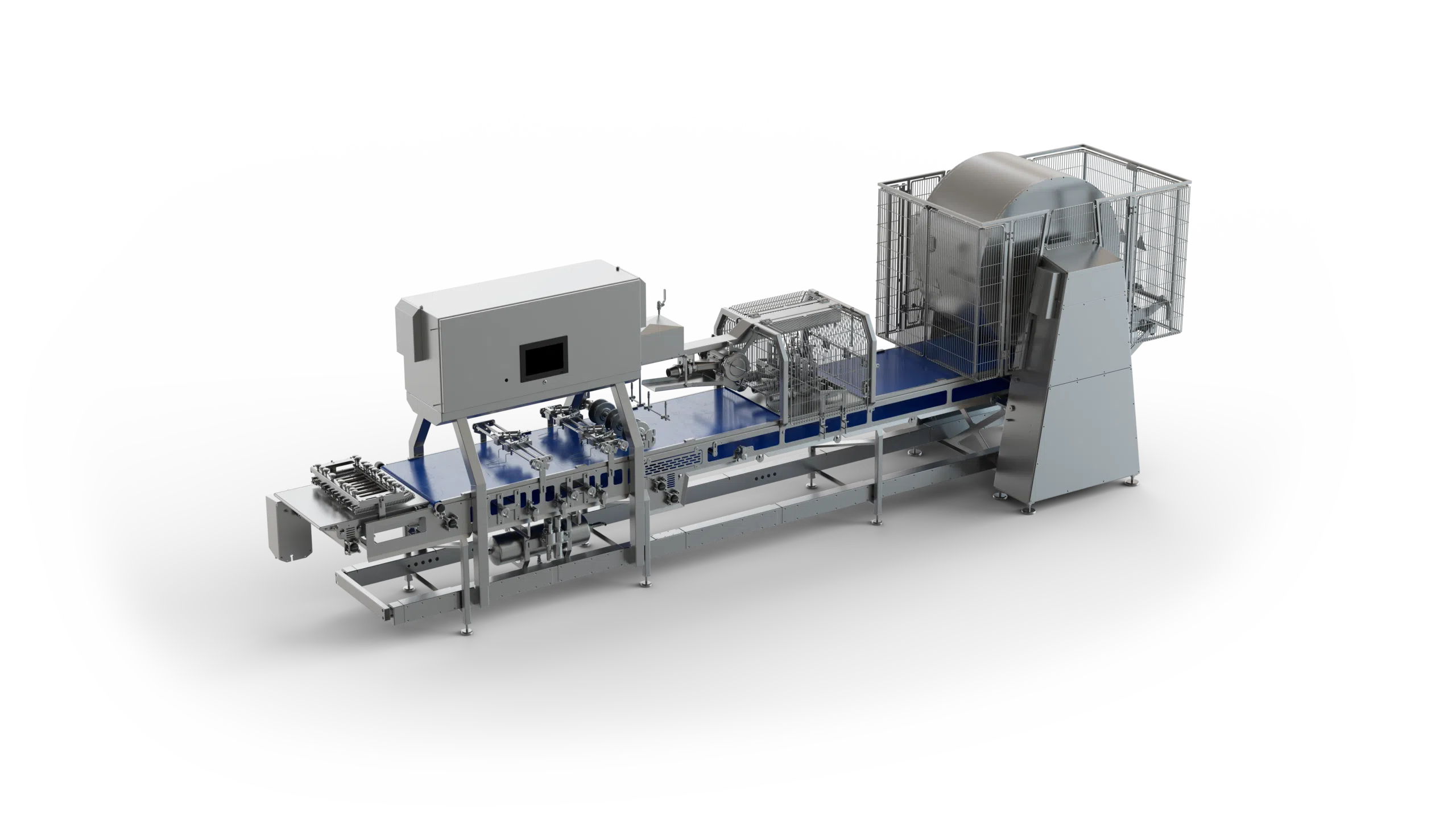

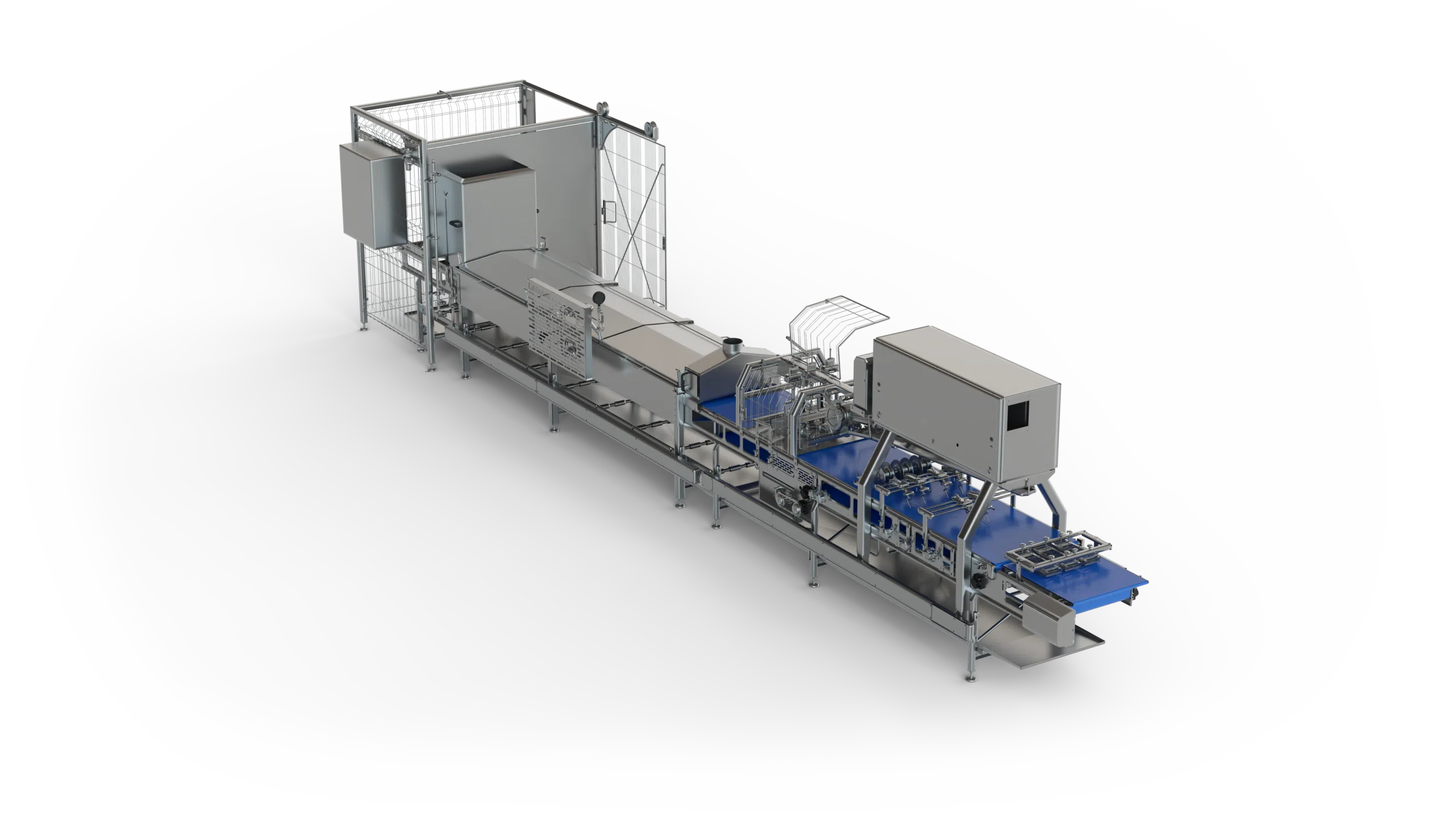

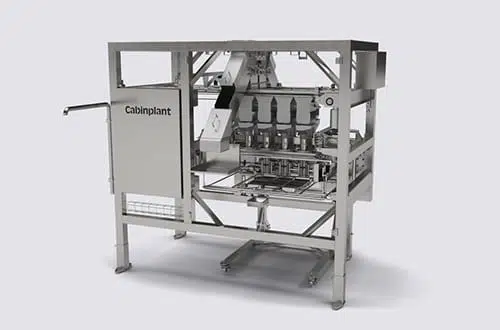

Contact our expertsFrom batter to crispy spring roll with no hands involved

Did you know there are a lot of advantages in investing in an automated spring roll line from Cabinplant including:

- Higher food safety due to minimized risk of cross-contamination

- Decrease in recruitment costs

- Save production space

- Downtime only 30 min pr product turnover

Sign up on this form and learn more about you can grow your business with an automated solution for your production of spring rolls.

Send the result

Your results have been sent

Calculated as an average

Size of the spring roll sheets? -; 145 millimeters

Benefit from 50+ years of experience

Our solutions are developed by combining our weighing technology experience with our 50+ years of experience within other areas of the food industry. We tailor-make solutions to match individual requirements, and we provide complete solutions for weighing, filling and packing products into bags, buckets, cans, glass jars, cups and trays; premade, thermoformed etc.

References

Cabinplant has backed us up all the way through our project; from the preliminary tests in Denmark up until the final running-in of the line after industrial trials on site. The teams have proved receptive to our demands and were able to meet our requirements. During the start-up phase, Cabinplant has supported us on site and by remote service to obtain our goals.

Related products

Contact a specialist

Have a question?

We’re here to help

Looking for the right solution for your food processing needs? Our team of specialists is ready to help you optimize your production, reduce waste, and boost efficiency. Reach out to us today — let’s explore how we can support your business.

Phone: +45 63 73 20 20

Email: cpi@cabinplant.com

Please allow all cookies to view this content.