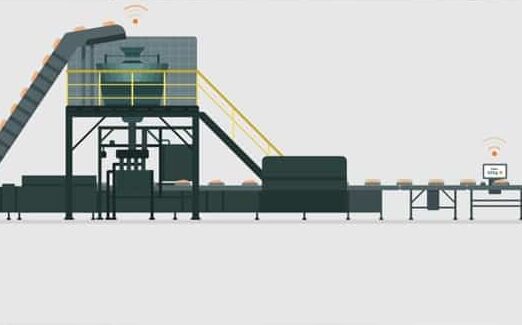

In-line marinating line

Impact

Our efficient packing solutions are designed to improve your business.

Nice and easy

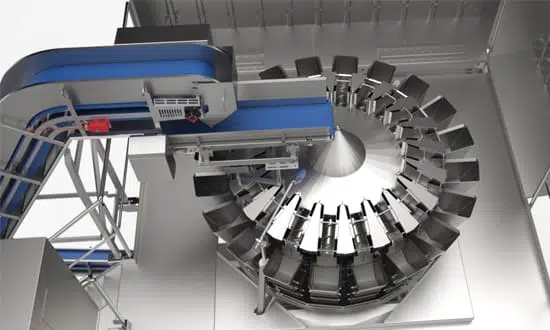

The marination process is done after portion weighing. Thus no marinade on the multihead weigher

80%

Marinating after portion weighing means a reducuction of the cleaning time by up to 80 %

20 minutes

Fast and easy change of marinade – less than 20 minutes

In-line marinating line makes it easier and faster to run small batches.

For suppliers of marinated products, we’ve seen that reducing downtime spent on cleaning their weighing and packaging equipment is an often overlooked way to cut labor costs while

increasing yield.

These kind of small, but smart gains add up to big savings and a significant increase in overall productivity.

Want to know more? Let’s talk!

Want to know more?

Does this solution fit your requirements? At cabinplant we are experts in creating the right customized solution. Get in touch with one of our specialist and learn more about how this solution will fit into your project.

Yes, contact me about my project"*" indicates required fields

Products in solution

Customize your solution

Designing food production equipment is often a question of combining various existing technologies in new and innovative ways. That’s one of our core skills - to meet the challenges you give us, while applying everything we know about automation, robotics and mechanical engineering.

We use our skills and long market expertise in designing a production line which is tailor-made to your needs and specifications. And of course, everything we design is constructed by top specialists.

Contact a specialist

We have people all around the world who can help.